Our Services

Forging. Machining. Gear Manufacturing – Delivered with Precision.

Delivering precision-engineered components through advanced forging, machining, and gear manufacturing technologies. With world-class infrastructure and strict quality systems, we provide reliable, high-performance solutions for global industries.

- Forging

- Machining

- Gear Manufacturing

- Precision Components

- Global Quality Standards

- OEM & Tier-1 Supplier

- Advanced CNC Infrastructure

- Reliable Delivery

- IATF 16949 Certified

- Forged Components

- Machined Parts

- Gear Accuracy DIN-5

- Automated Quality Control

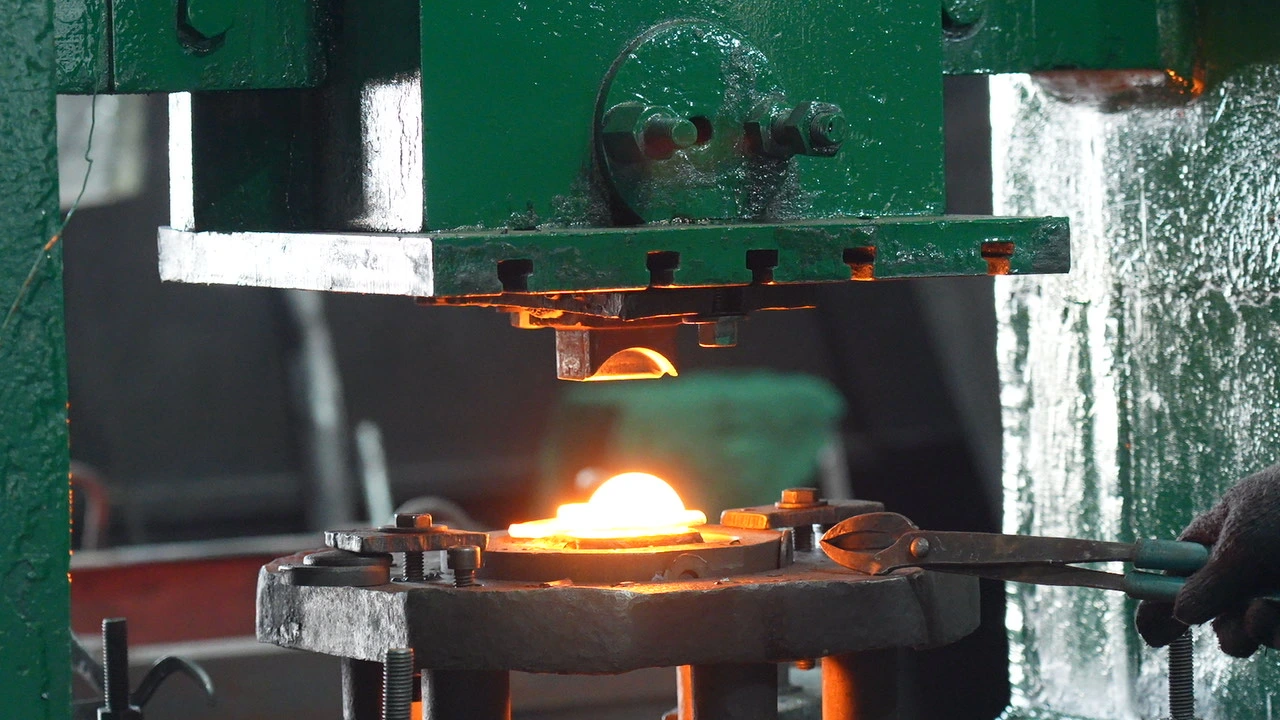

FORGING :

Metalic Technoforge (MTF) offers advanced closed-die forging capabilities designed to deliver high-strength, high-precision components for demanding industries. With modern forging hammers, presses, induction billet heaters, and in-house heat treatment, we ensure complete control over material properties, dimensional accuracy, and consistency.

Forging Facilities :

– 3 Lines

– 2 Lines

– 5 Lines

– 2 Lines

Call us now. +91 9033356105

MACHINING :

Our machining division is equipped with latest-generation CNC Turning Centers, Vertical Machining Centers, broaching machines, and finishing equipment – ensuring accuracy, repeatability, and premium surface finish. With IIoT-enabled monitoring, we guarantee consistent quality, minimized downtime, and high throughput.

Machining Facilities :

CNC Turning & Milling Centres

Broaching Machines

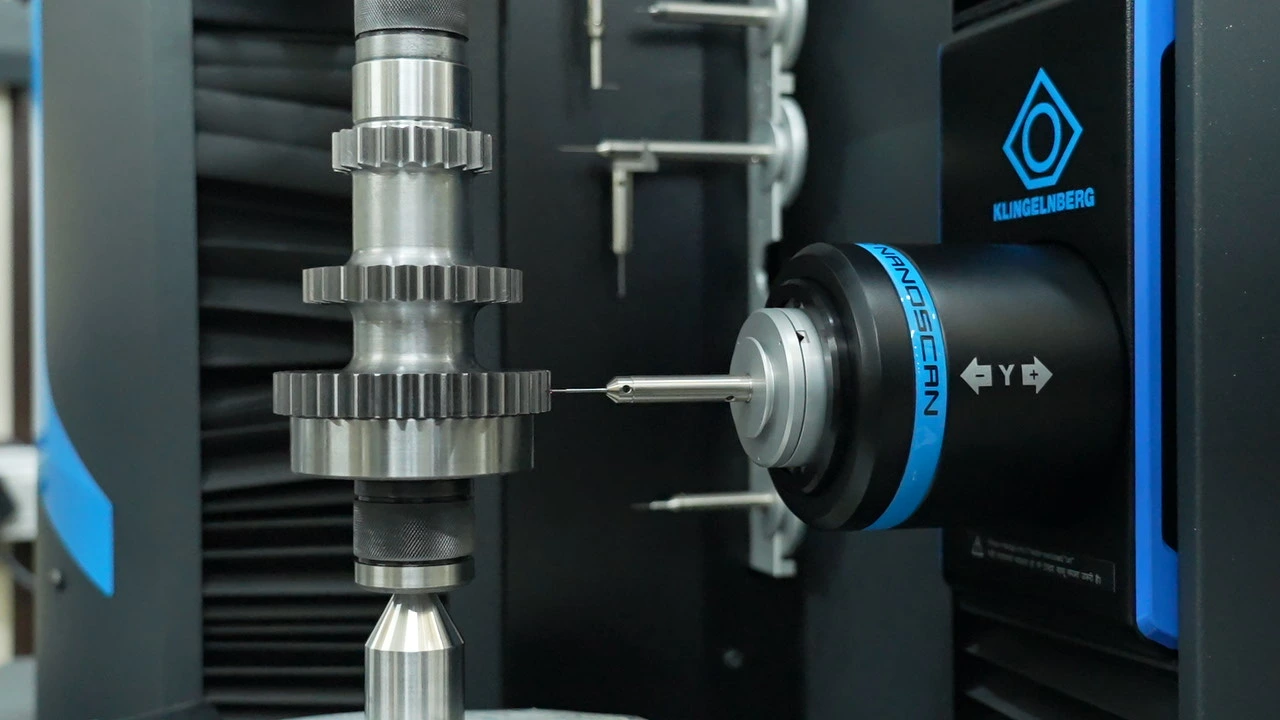

Gear Profile Grinder – Klingenberg Viper 500

CNC Gear Hobbing – Nidec

Call us now. +91 9033356105

GEAR MANUFACTURING :

MTF specializes in gear manufacturing using advanced CNC gear hobbing, shaving, and profile grinding technology. With premium-grade forged blanks produced in-house, we ensure optimal gear strength, microstructure integrity, and long service life.

Gear Manufacturing Facilities :

– Klingenberg Viper 500

– CNC Gear Hobbing

– Klingenberg P40

Broaching & finishing operations

Call us now. +91 9033356105