Trusted by Global Industries

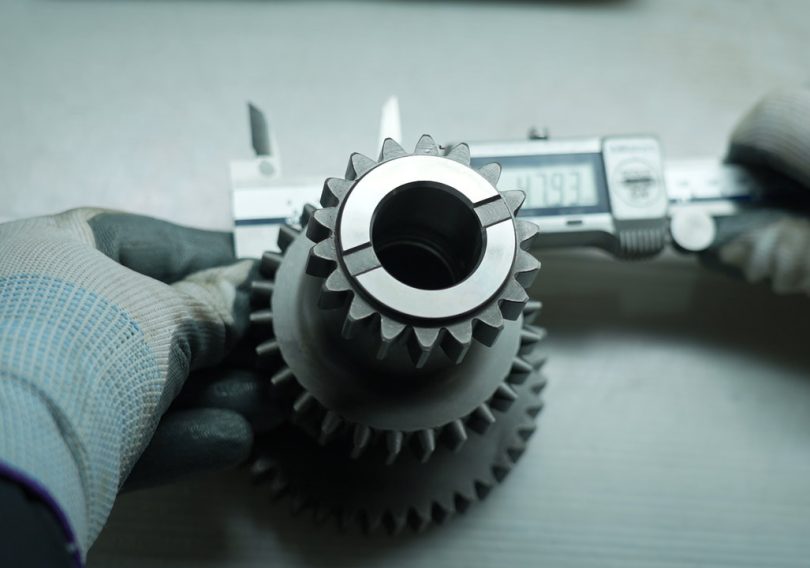

Precision-Forged & Machined Components

Your Trusted Partner in Precision Manufacturing

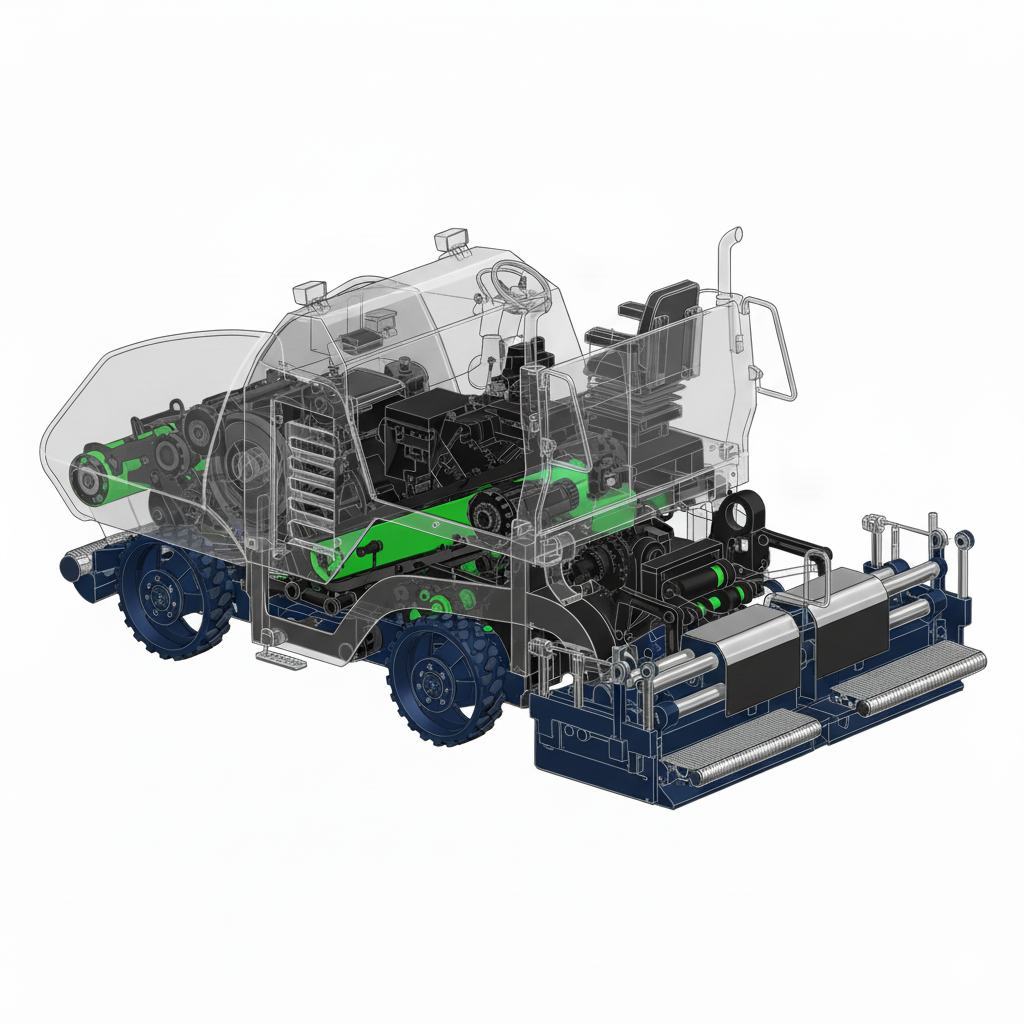

Metalic Technoforge Limited specializes in delivering high-precision forged, machined, and assembled components for a wide range of global industries. With an integrated manufacturing setup – covering forging, machining, heat treatment, coating, and assembly – we maintain complete control over every stage of production, ensuring consistent quality and reliable performance.

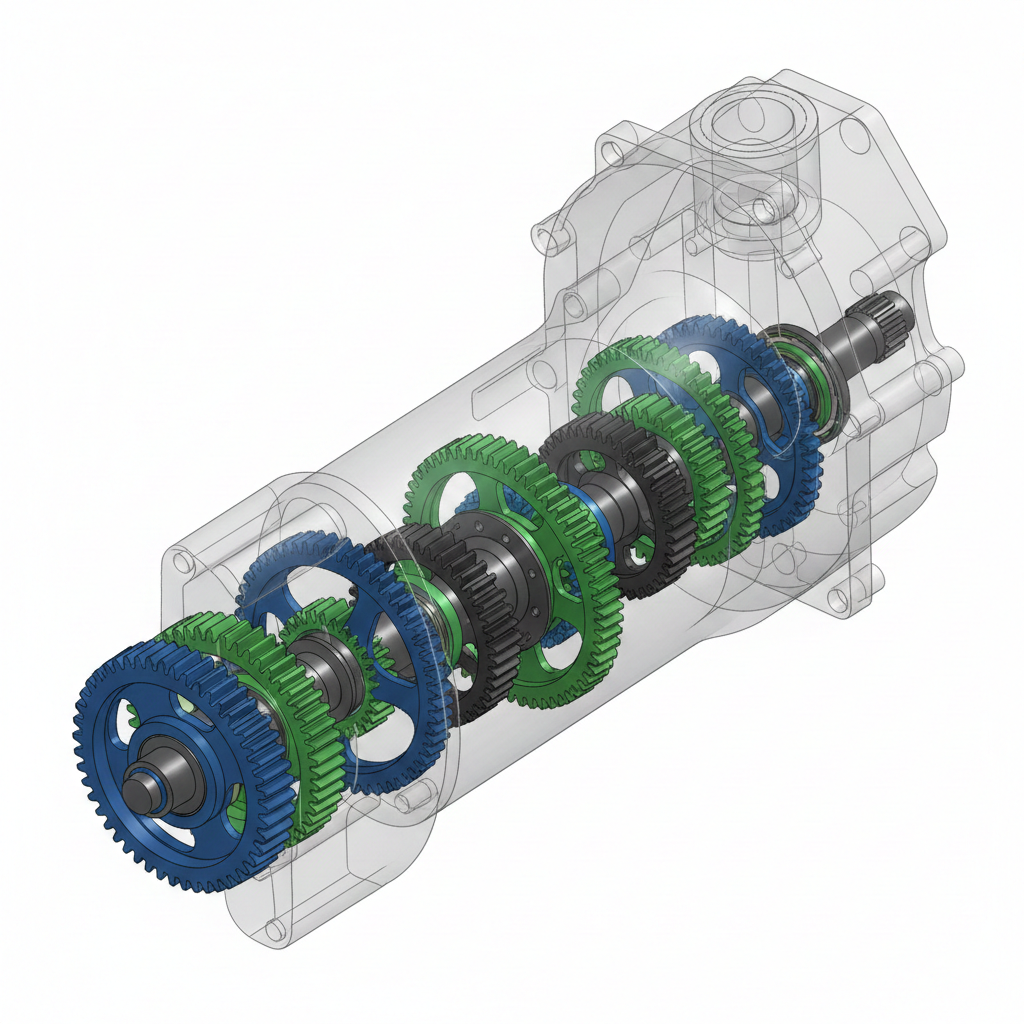

Our capabilities span closed-die forging, CNC machining, gear manufacturing, assembly operations, and value-added services – all supported by strict quality systems and customer-specific process control. From induction heating and forging to machining, coating, and assembly, we manage the complete manufacturing cycle in-house, ensuring consistent quality, shorter lead times, and cost-effective production.

Our Services

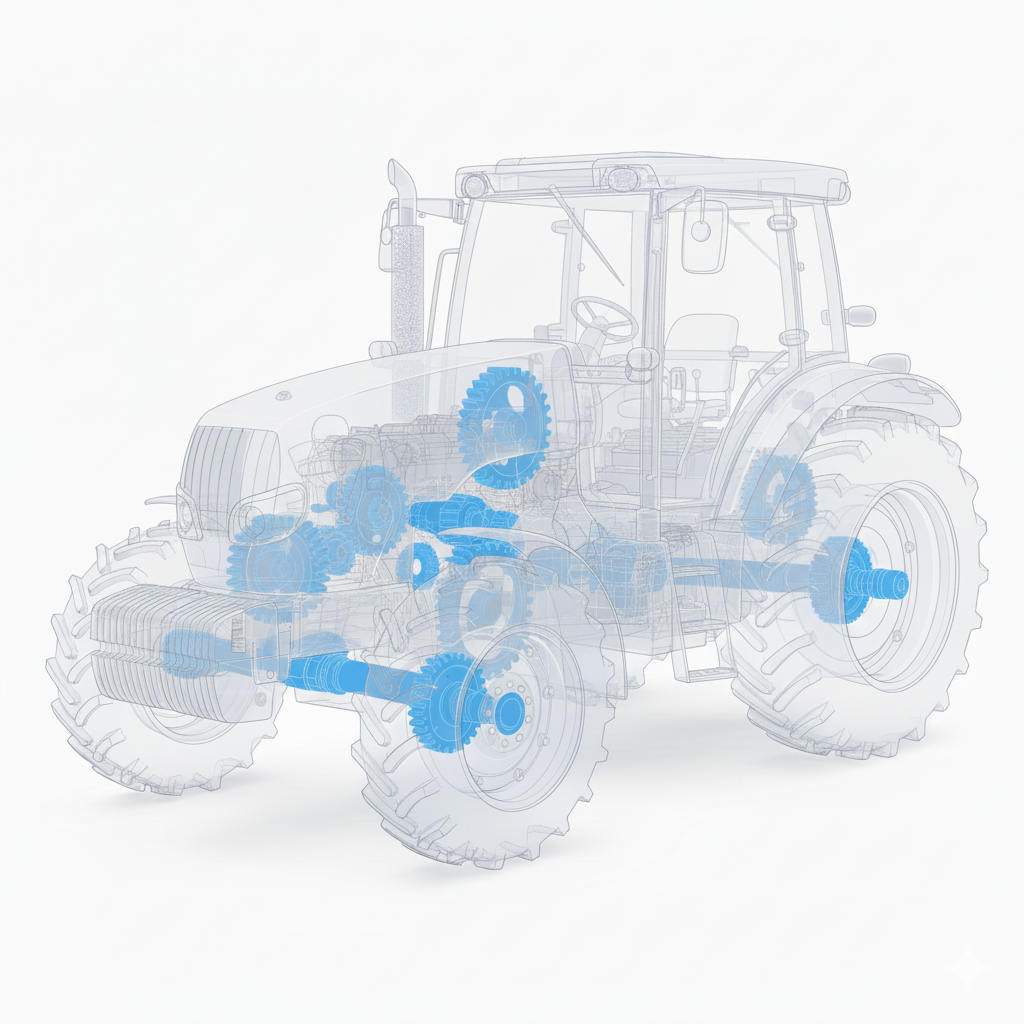

Gear Manufacturing

Numbers That Define Our Excellence

Quality you can trust, precision you can count on.

01.

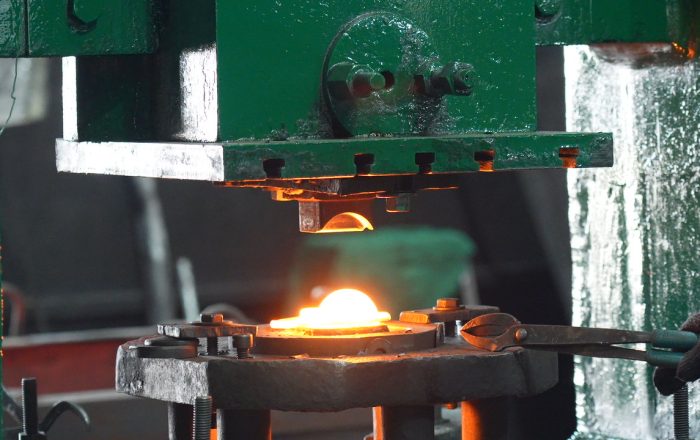

High-Performance Hot Forged Parts

02.

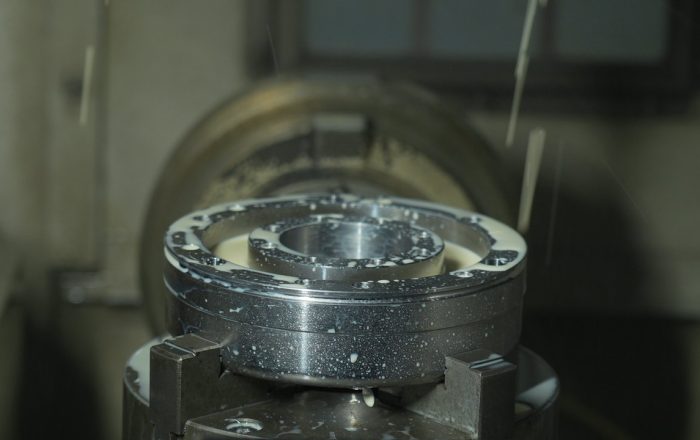

Advanced In-House Machining Capabilities

03.

Complete Assembly Solutions

04.

In-House Heat Treatment & Premium Coatings

” Advanced forging, machining, and assembly capabilities powered by strict quality control. “

Engineered Solutions for Every Industry

01

02