Why integration matters

In industries where performance and reliability matter – automotive, hydraulics, construction and more – component quality begins long before final inspection. The best outcomes come from an integrated manufacturing chain where forging, machining, heat treatment and assembly operate under a single quality system. Metalic Technoforge’s blended approach reduces lead time, improves traceability, and delivers parts ready for immediate use.

End-to-end process control

Controlling each production step – from raw material handling and induction heating to forging, machining, and post-process coating – removes variations that typically occur when work is passed between vendors. MTF operates a modern forging line backed by induction billet heaters and in-house heat treatment to achieve consistent metallurgical properties across batches. These capabilities ensure optimal grain flow and mechanical properties in every forged component.

Advanced machining for precision finishes

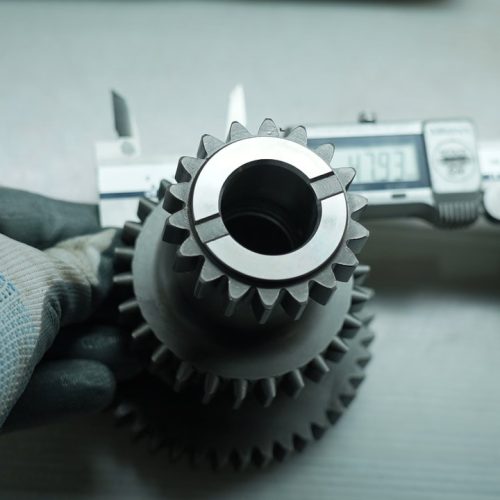

After forging, precise CNC turning, milling, broaching and grinding are essential to meet tight tolerances. MTF’s machining workshop includes vertical machining centers, turning centers and specialized gear grinders that refine forged blanks into finished parts. Integrated IIoT-driven monitoring and high-precision inspection equipment ensure dimensional conformity and repeatability.

Quality systems and inspection

Quality assurance is not an afterthought. MTF’s inspection suite – featuring ZEISS CMM, contour testers and gear profile testers – validates form, fit and function before parts ship. These systems allow 100% traceability and faster acceptance by OEMs and Tier 1 clients.

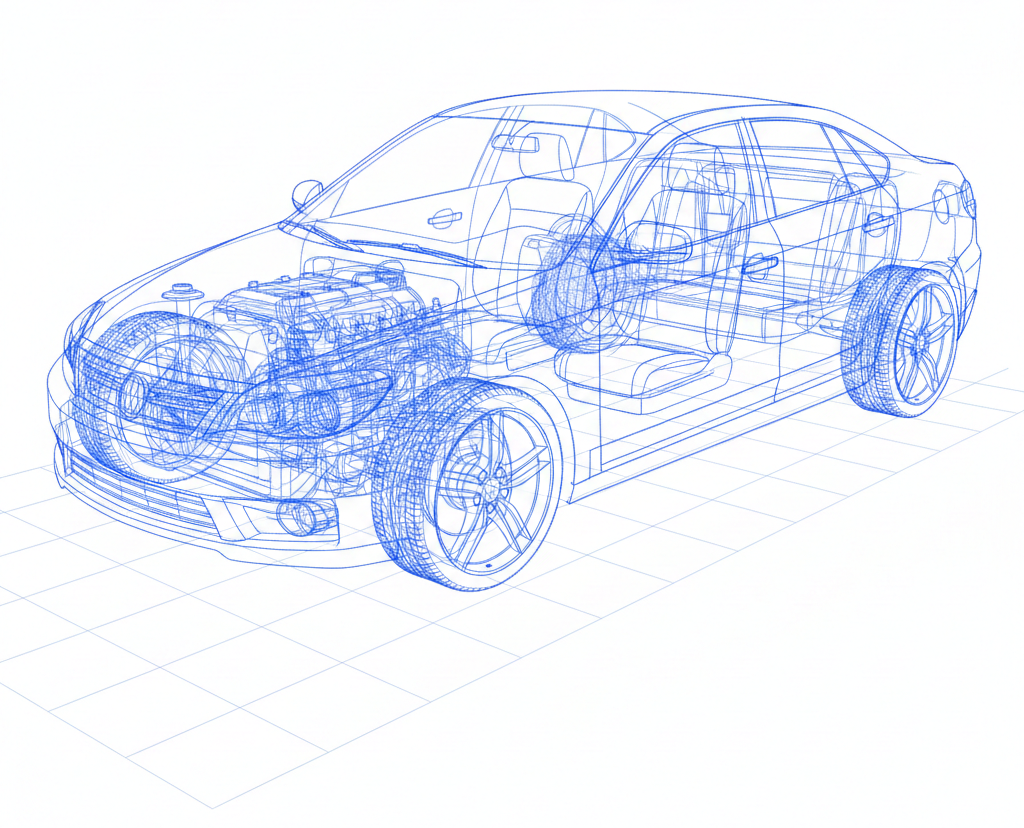

Value-added assembly capability

Supplying assembled products (including standard parts, plastics and rubber components) reduces the customer’s assembly burden and shortens time-to-installation. MTF’s experience handling complex BOMs for European markets positions the company as a turnkey supplier for clients needing ready-to-install subassemblies.

Business benefit: lower risk, faster delivery

Integrated factories reduce logistics complexity and the risk of non-conforming multi-vendor parts. By keeping forging, heat treatment and machining in-house, MTF shortens development lead time and improves on-time delivery performance – critical metrics for global customers.