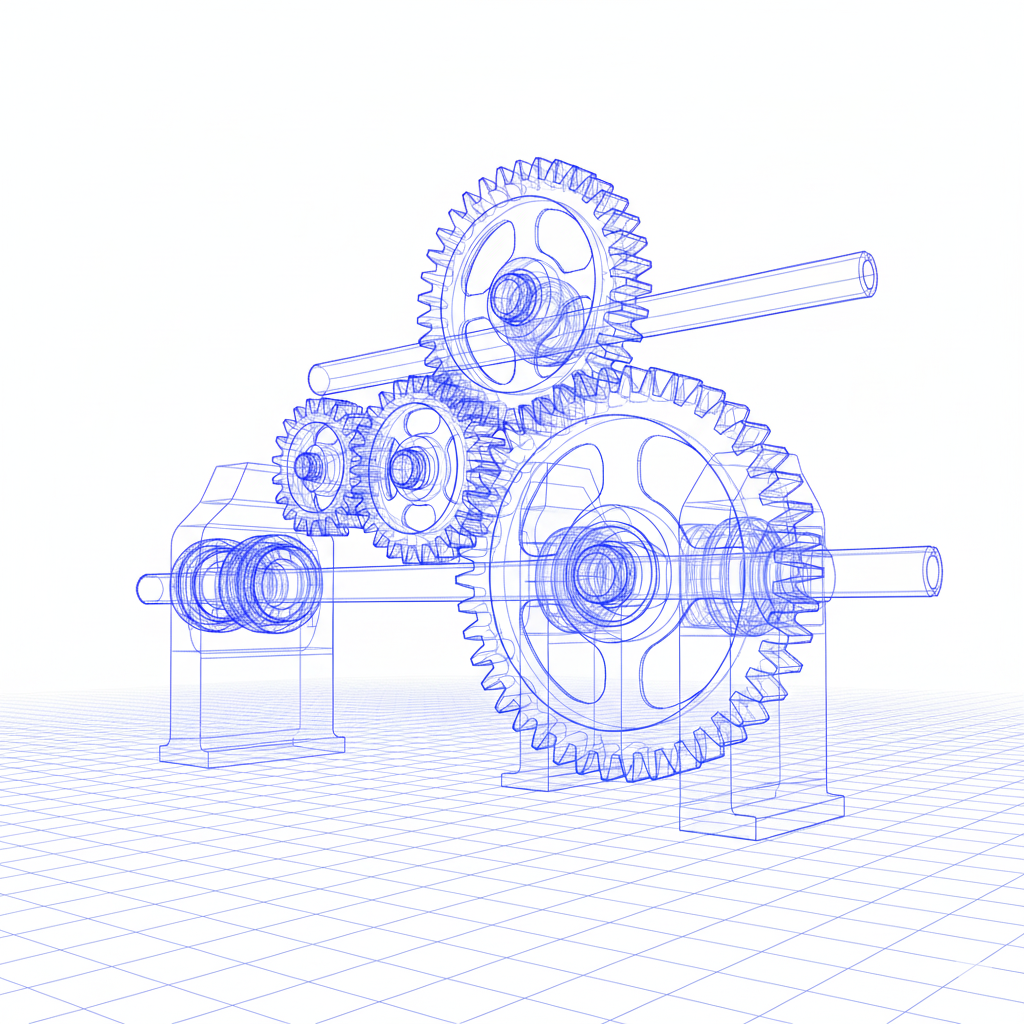

Why gear precision matters

Gears are fundamental to motion control, power transmission and machine reliability. Small deviations in tooth geometry or surface finish can cause noise, vibration and premature wear. That’s why DIN-class accuracy and stringent testing are essential for critical applications.

From forged blanks to finished gears

MTF transforms forged gear blanks into precision gears using an integrated process: CNC gear hobbing, gear profile grinding (Klingelnberg / Viper 500), gear shaving and broaching. Working from a forged blank delivers improved mechanical strength compared to cast or sintered alternatives, especially under cyclical load.

Advanced gear cutting & finishing

High-accuracy hobbing machines, gear grinders and shaving equipment refine tooth geometry to achieve precision classes up to DIN-5. These processes control lead, profile and pitch errors so gears mesh quietly and transmit power efficiently over long service life. MTF’s lineup includes specialized gear equipment and dedicated broaching capability for splines and internal profiles.

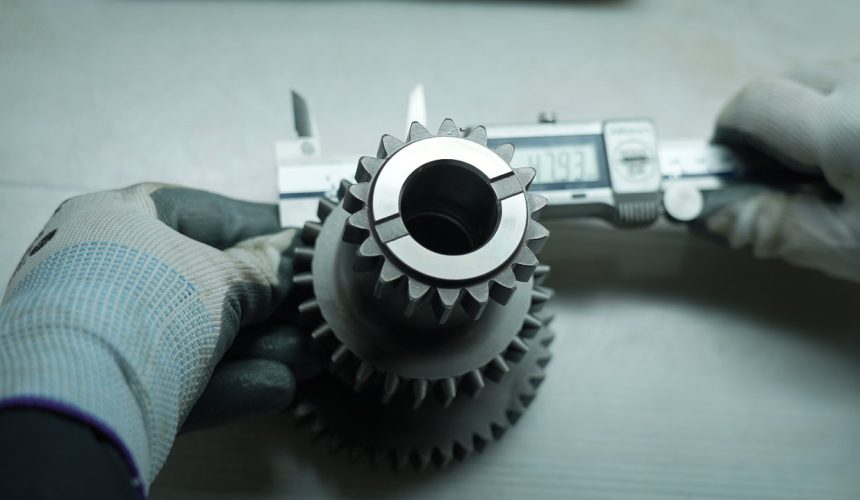

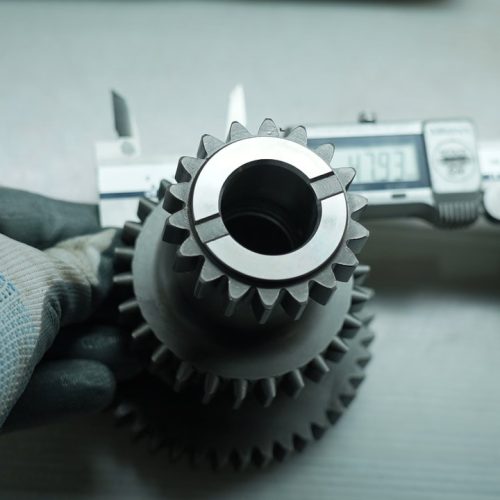

Gear inspection — guaranteed performance

Producing a high-precision gear is only half the job; verifying it is where reliability is proven. MTF employs gear profile testers, ZEISS CMM and contour measurement equipment to validate every critical dimension and surface finish before shipment. This testing ensures each batch conforms to customer specifications and international standards.

Applications & benefits

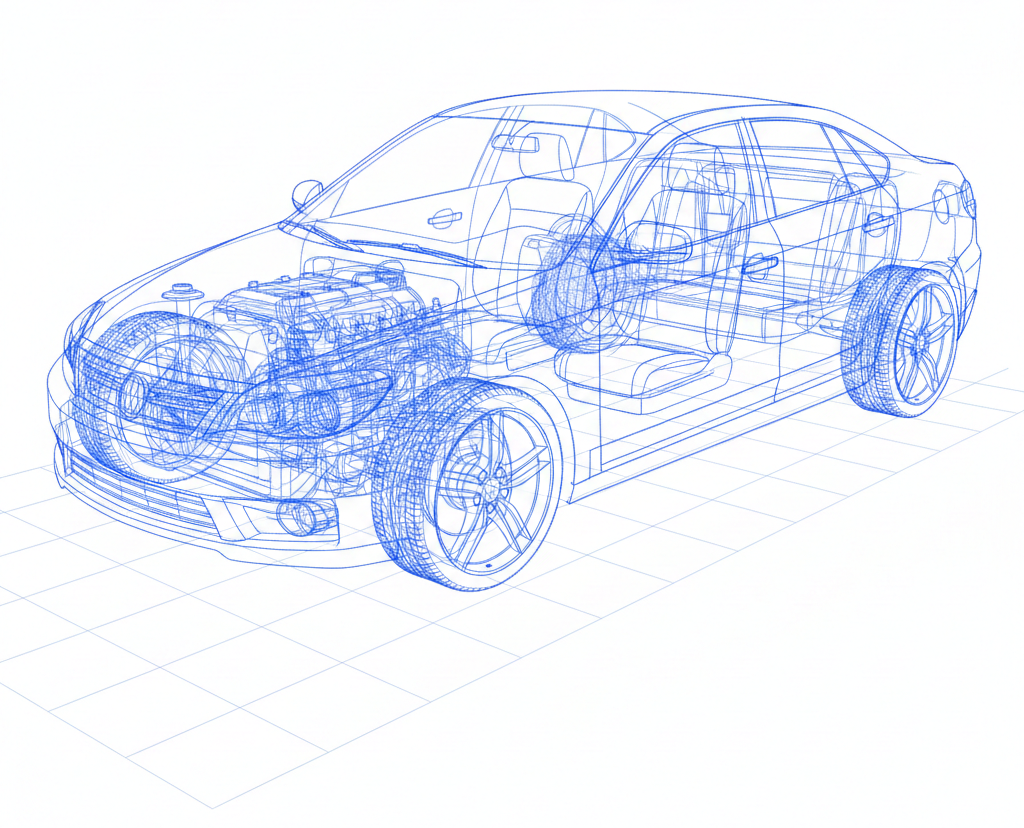

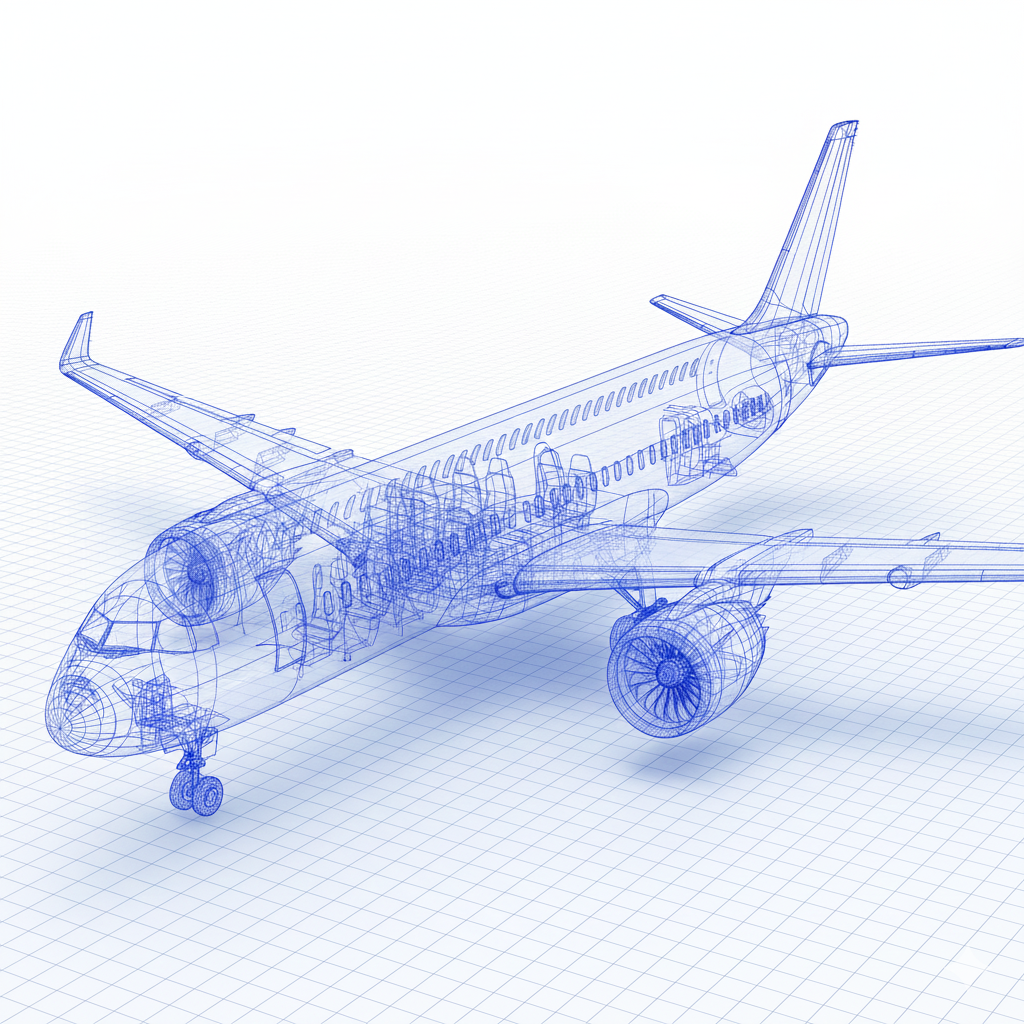

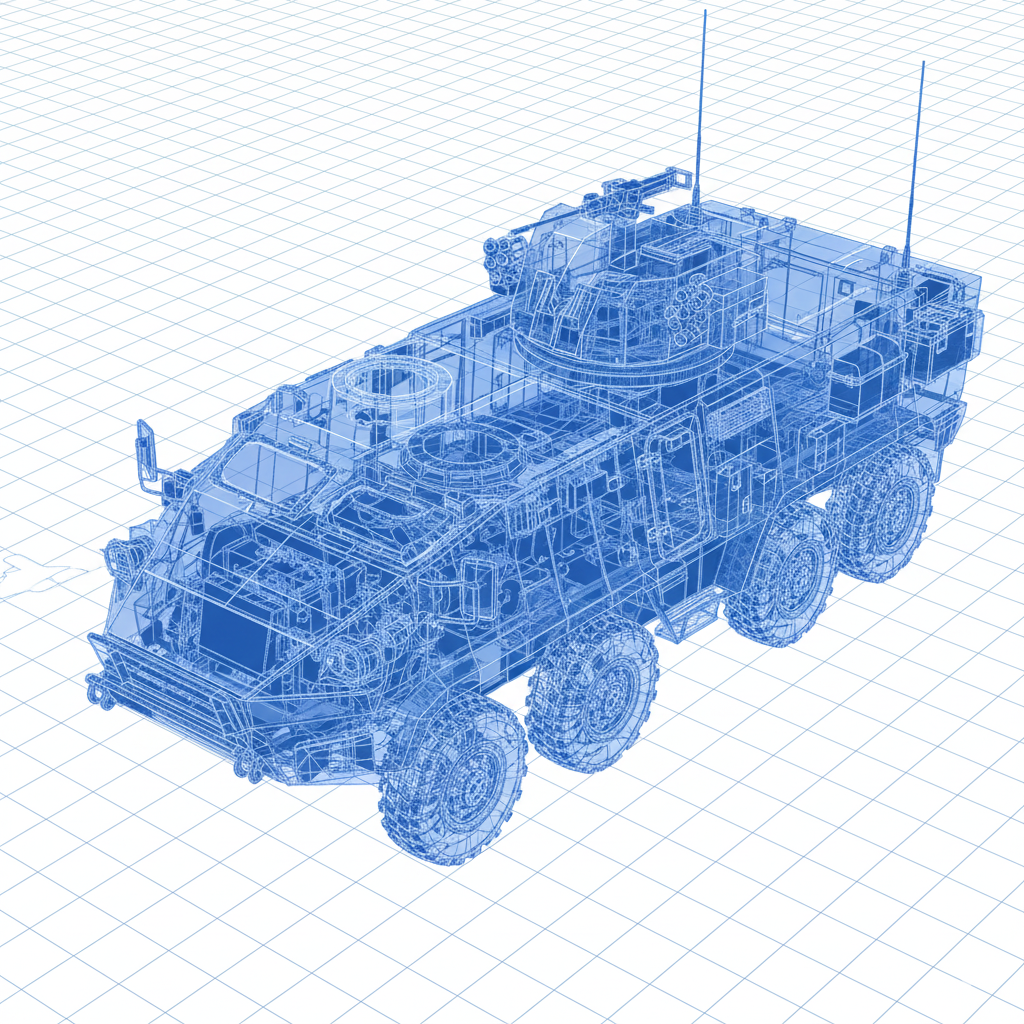

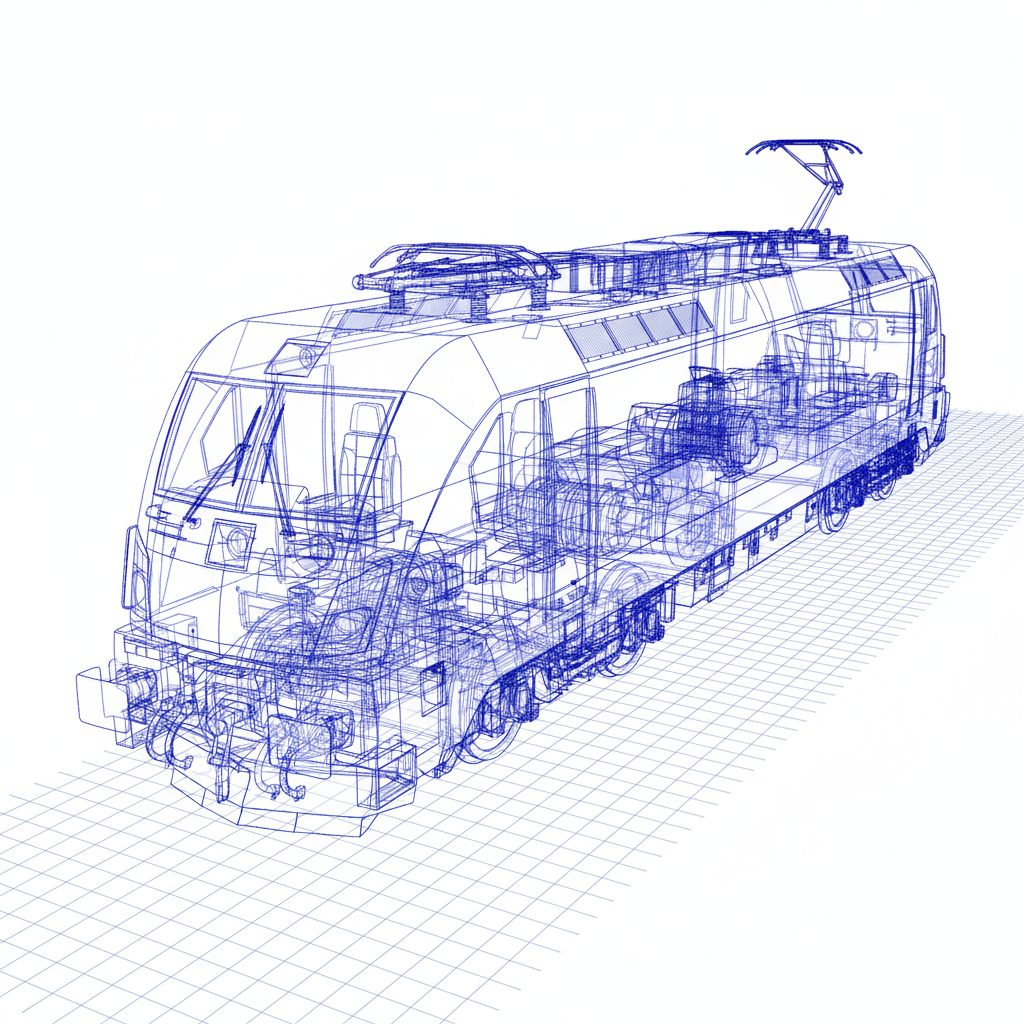

Whether for automotive transmissions, construction equipment, or hydraulics, DIN-class gears offer quieter operation, higher efficiency and longer durability. By combining forged blanks, precision machining and rigorous testing, MTF supplies gears that perform reliably in the harshest operating conditions.