How Forging Defines Strength and Precision

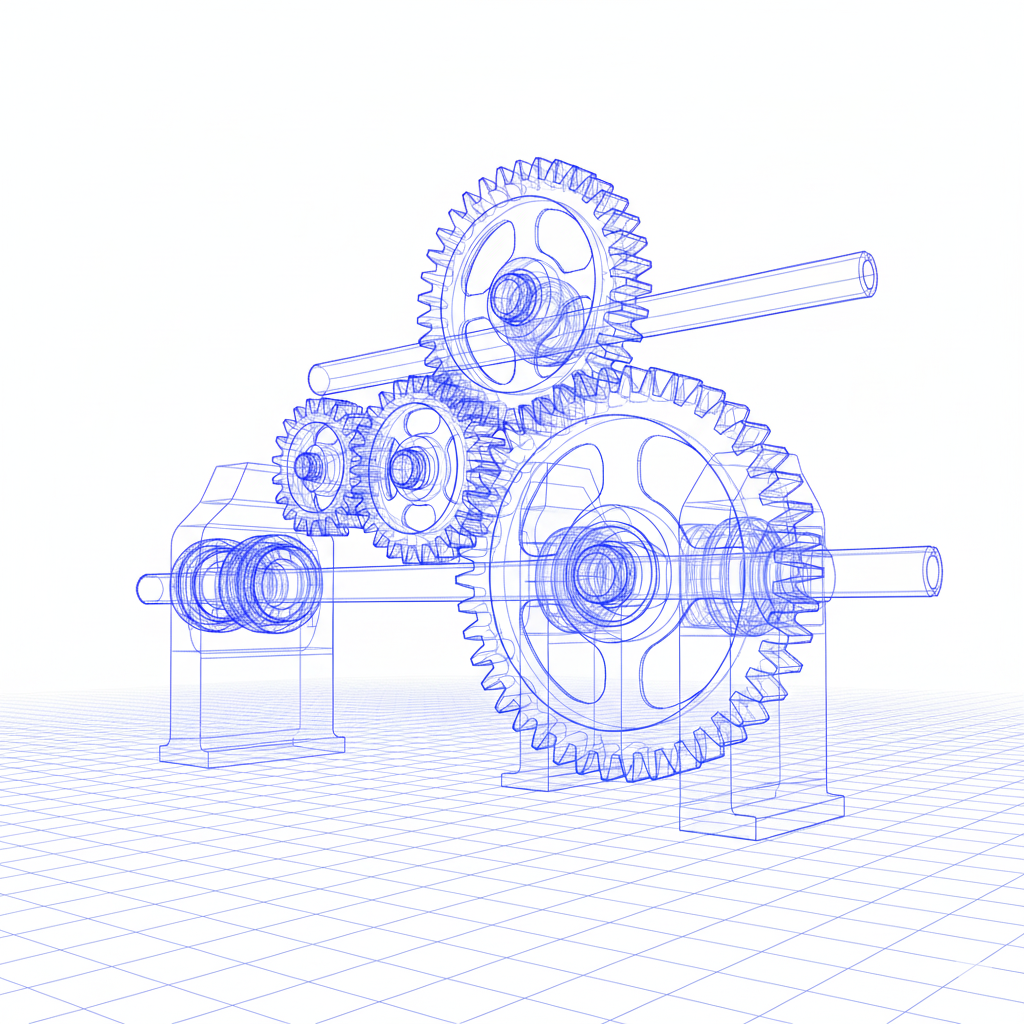

MTF specializes in manufacturing high-strength closed-die forged components designed for OEMs, Tier-1 and Tier-2 customers across Automotive, Construction, Agriculture, Hydraulics, Oil & Gas, and General Engineering sectors. With state-of-the-art forging lines, induction heating systems, and in-house heat treatment capabilities, we ensure consistent quality, superior mechanical properties, and exceptional repeatability for every part we produce.

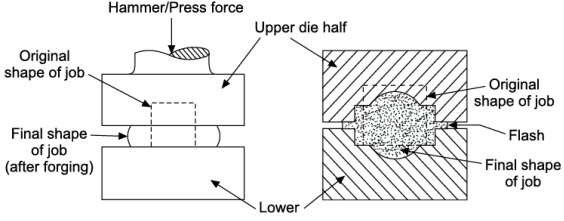

Our forging division operates with advanced screw presses, hammers, and induction billet heaters that enable precise control over deformation, temperature, and material flow. Each component is engineered to meet stringent global standards and custom specifications.

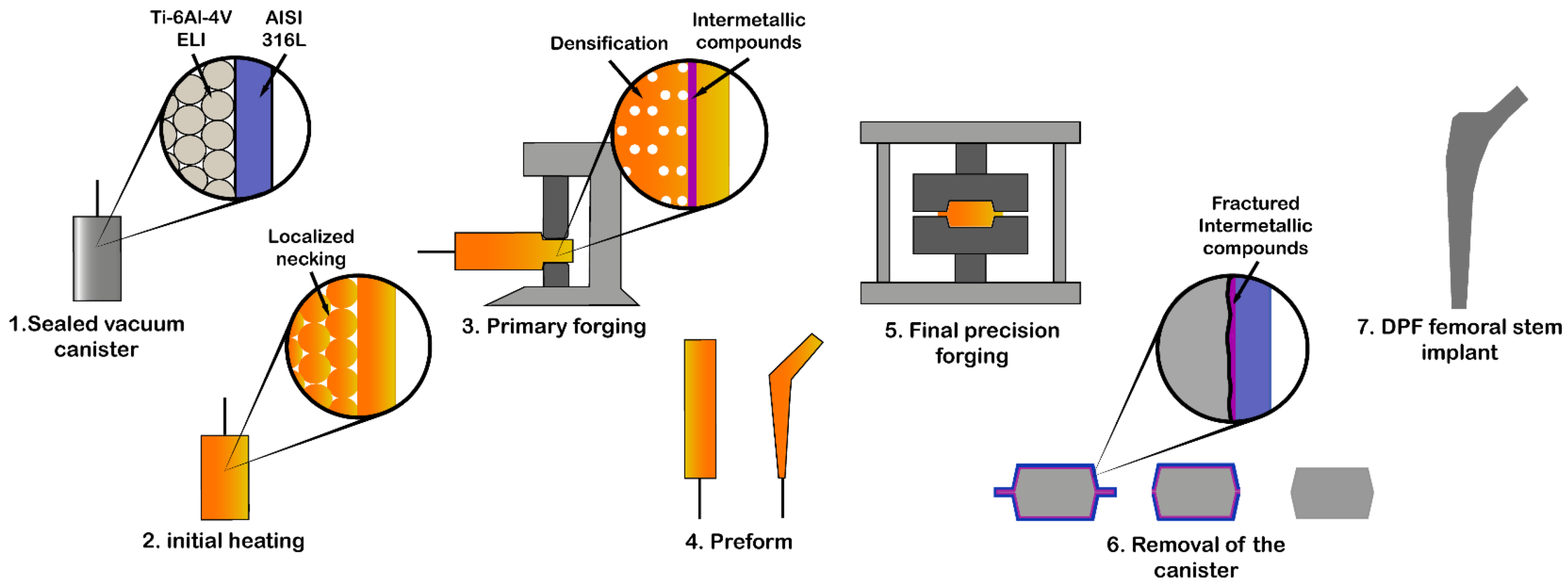

Our Step-by-Step Forging Process

A Fully Controlled, End-to-End Manufacturing Workflow

Raw Material Selection & Testing

Induction Billet Heating (5 Lines)

Closed-Die Forging (Screw Press & Hammer Lines)

Trimming & Flash Removal

In-House Heat Treatment (2 Furnaces)

Shot Blasting & Surface Finishing

Final Inspection & Testing