How Precision Gear Manufacturing Powers Global Industries

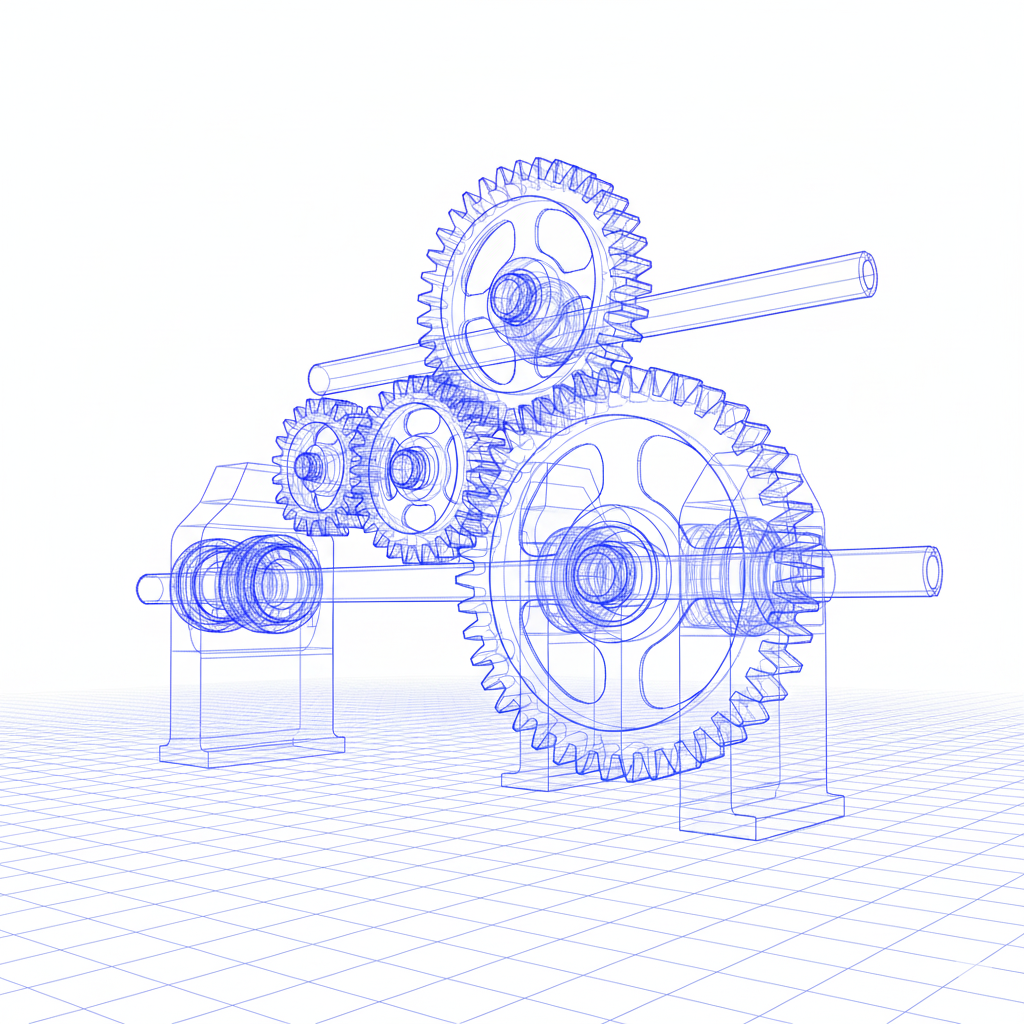

At Metalic Technoforge, we specialize in producing high-precision gears engineered for durability, accuracy, and demanding performance conditions. By combining forged raw materials with advanced CNC gear cutting, shaping, shaving, and grinding technologies, we deliver gears that meet up to DIN-5 accuracy class, ensuring exceptional operational reliability.

Our shop floor operates on IIoT-based monitoring, enabling real-time data tracking, predictive maintenance, tool-life optimization, and process consistency. Every part undergoes strict in-process and final inspection using Zeiss CMM, contour testers, and surface roughness testing, ensuring zero-defect components tailored to global OEM requirements.

Our Gear Manufacturing Process

A complete, controlled workflow ensures high accuracy, durability, and consistency in every gear we produce.

Forging & Raw Material Preparation

Turning & Pre-Machining

Gear Hobbing

Gear Shaving / Finishing

Gear Grinding (Up to DIN-5 Accuracy)

Broaching / Keyway Cutting

Heat Treatment (In-House)

Final Inspection & Quality Validation

Why Our Gear Manufacturing Stands Out

01.

Gears Made from Forged Parts

02.

High Accuracy – Up to DIN-5 Class

03.

End-to-End Gear Solutions

04.

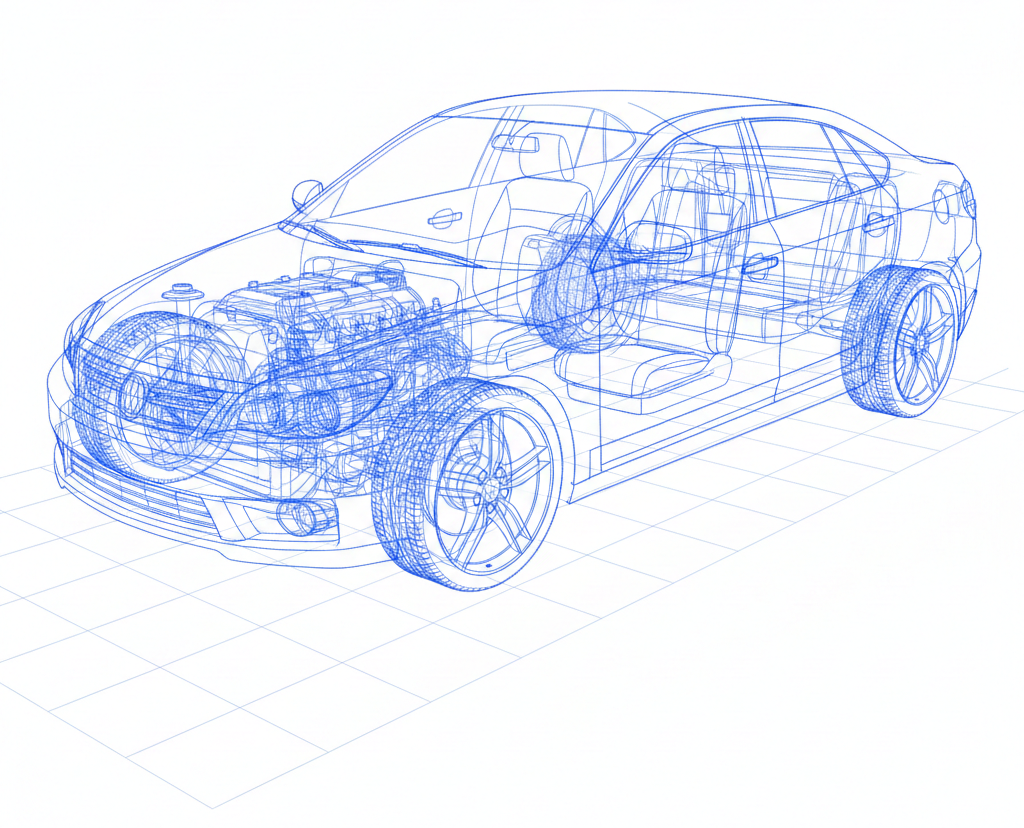

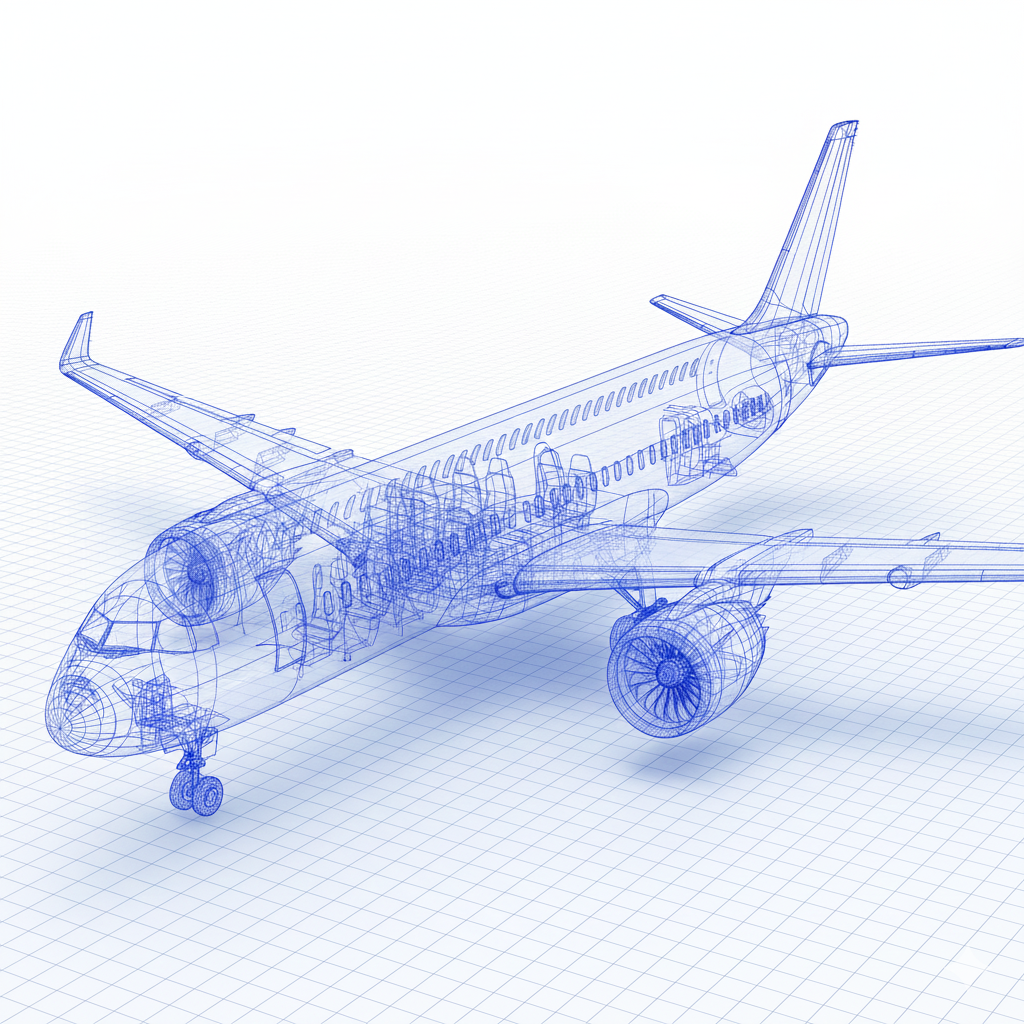

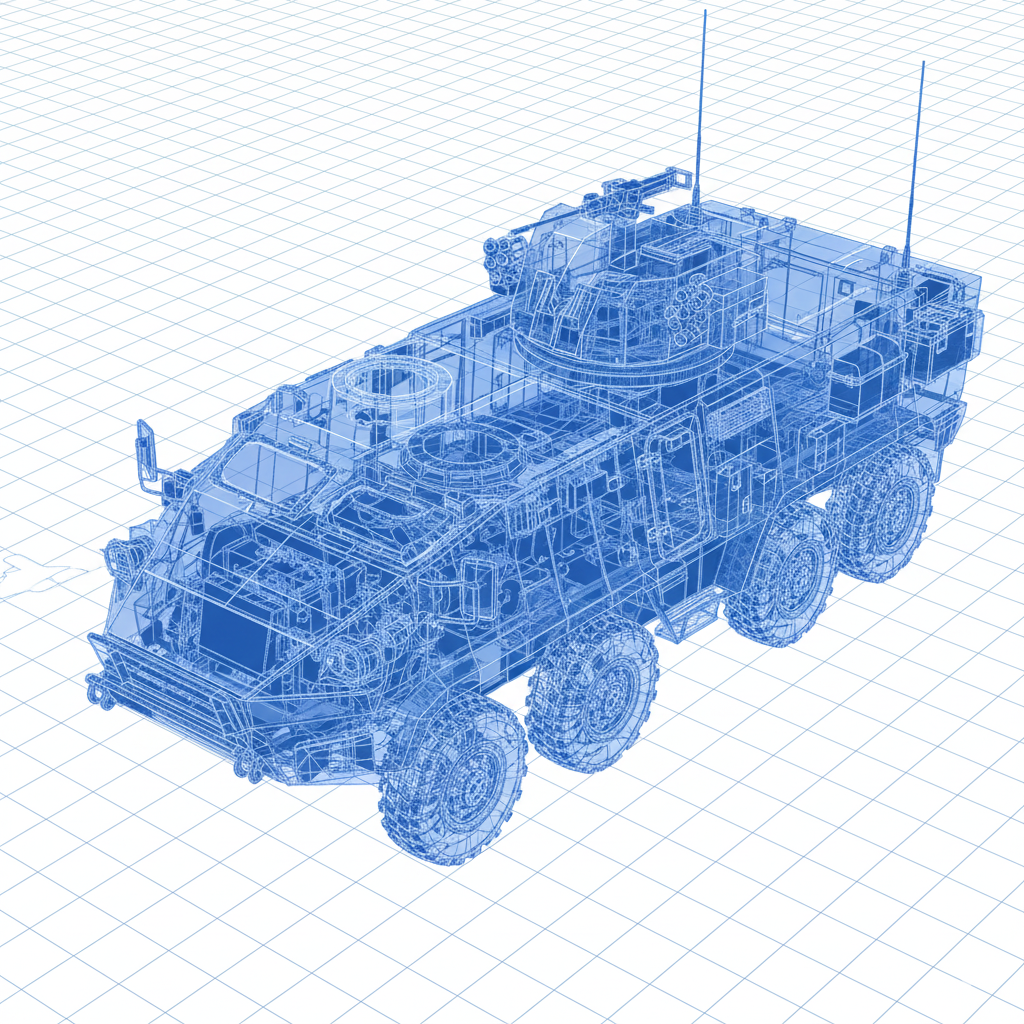

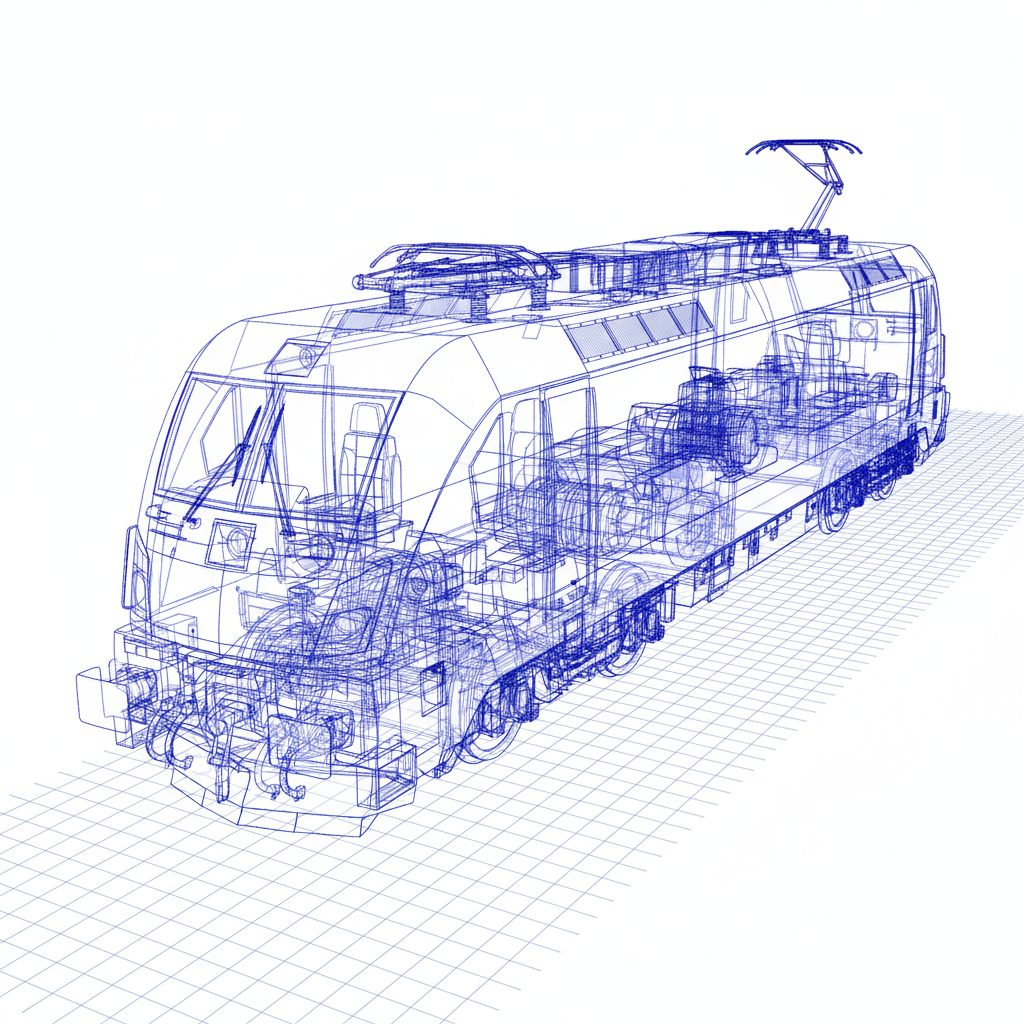

Wide Range of Gear Types

05.

Advanced Inspection & Quality Assurance

06.

Trusted by Global OEMs

Our Gear Manufacturing Infrastructure

02.